Something good can still get better

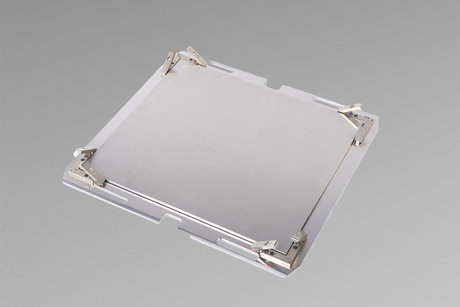

Precision knows no compromises. Nor does our quality. Every individual employee at C.A.PICARD® is responsible for this goal. Our personal commitment starts with the initial discussion and carries further than our refurbishing service. That is how we can assure that you receive the carrier plates which are technically and economically optimal for your requirements and application.

| Carrier plates / Bottom and top plates | ||||

|---|---|---|---|---|

| Steel quality: | DIN 42 CrMo4 AISI 4140 H | DIN 50 CrV 4 AISI 6150 H | 1.4021 X 20 Cr 13 | |

| Hardness: | 40 ± 2 HRC | 40 ± 2 or 50 ± 2 HRC | 40 ± 2 HRC | |

| Thermal expansion coefficient: | 12 x 10-6 / °C | 11.5 x 10-6 / °C | ||

| Heat conductivity: | 42 W/mK | 30 W/mK | ||

| Working temperature: | ≤ 400 °C | ≤ 400 °C or ≤ 250 °C | ≤ 300 °C | |

| Dimensions and tolerances | Standard | Premium (for all versions) | ||

| Length / Width: For large formats 2000 mm: | ± 0.5 mm + 3 – 5 / -0 mm | |||

| Thickness: | ± 0.2 mm | |||

| Wire cut registration holes: | on request | |||

| Flatness: | 0.2 – 3.0 mm – depending on size and thickness | |||

| Parallelism: For large formats 2000 mm: | ≤ 0.03 – 0.05 mm ≤ 0.1 mm | |||

| Surface finish: | Grit 80 Ra ≤ 1.2 – 2.5 μm | |||

| Available thickness: | 2.0 – 15.0 mm | up to 10 mm | ||

Press Plates with wire-cut registration holes on request. Variations to above mentioned tolerances and standard specifications possible on request. Subject to changes due to technical improvements without prior notice.