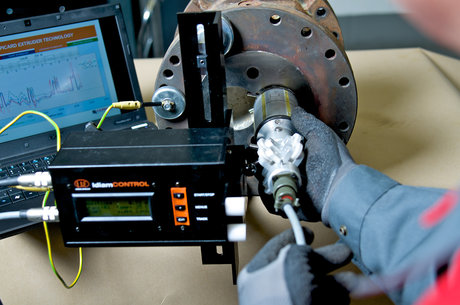

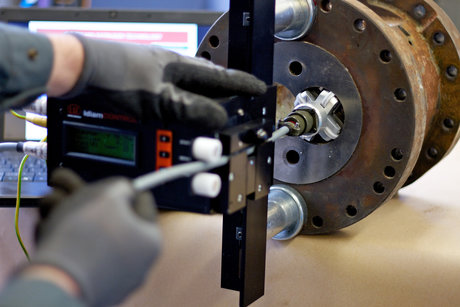

Barrel wear measurement service

We measure directly on the twin screw extruder and can therefore detect any wear in the barrel at an early stage.

Those who want to remain permanently productive have to detect wears and tears at an early stage. We are able to inspect the condition of the integrated barrels directly on your extruder line with our wear measurement service. The barrels only need to be clean and cooled down, but they will not be disassembled for this - thus saving you valuable time and maximising the benefits.

Our inspections ensure your productivity. If you detect any wears and tears, you can procure replacement parts in good time. Repairs can therefore be planned and calculated.

The benefits at a glance:

- Quick, cost-effective and on-site

- Preventive maintenance allows for reliable production

- Measurement and analysis at a fixed price

- All measurement results are documented.